Liberty consulting

Building

Modular Manufacturing

2011 - 2015

Full project details

The 224 meter building will become one of the most recognizable in the square mile, occupying a prominent site directly opposite the distinctive Lloyd’s of London headquarters.

The structure’s distinct asymmetrical shape – a response to planning requirements to maintain views of Cathedral – meant settlement both in the foundations and through compression of its elements would be irregular.

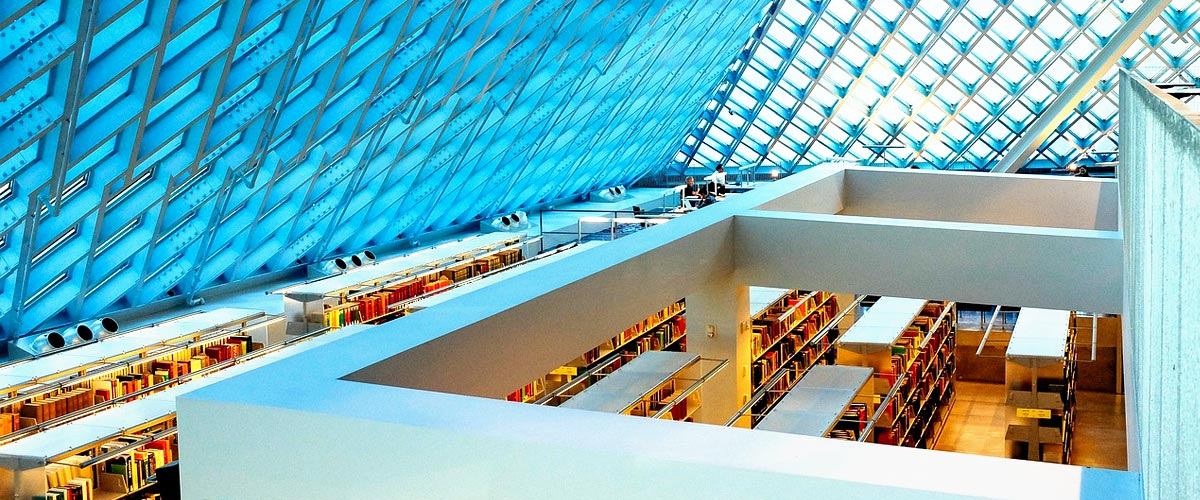

An iconic building

The development’s tapering shape, which when viewed from the west will appear to ‘lean away’ from St Paul’s Cathedral, delivers varied sizes of floor plates, all offering spectacular views over London. Practical completion of the shell and core is scheduled for mid-2014. The geometry of the 52-storey skyscraper makes it theoretically unstable.

Exceptional engineering skills were necessary therefore, to develop a construction methodology that enabled the building to stay upright – with tolerances of plus or minus 20mm required on all but five of its floors.

The team that was assigned to our project…were extremely professional throughout the project and assured that the owner expectations were met and often exceeded.

- Hamith Jonesten

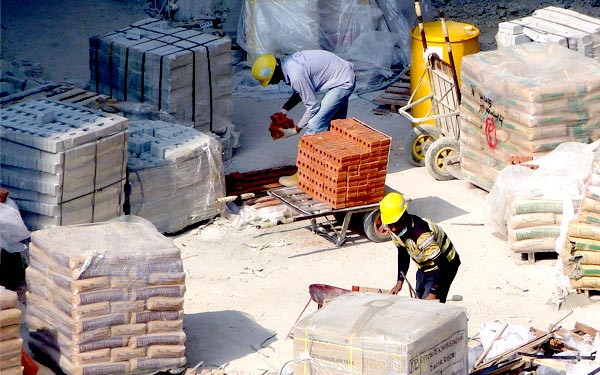

Logistics and DfMA

The intense public interest in the development leaves no room for logistical error. Its high-profile location – characterised by narrow and densely populated streets – along with the site’s remarkably tight footprint, represent considerable obstacles.

To work around these constraints, much of the structure – including the cores, basement and building services – will be constructed off site. However, with components of up to 26 metres in length this creates its own challenges. Once again, the team used BIM to perfect its strategy for just-in-time assembly.